Cart

Your cart is empty

Continue shopping

Product added to cart

男款

女款

Sale

News

Bike

-

量身訂製車|Bespoke Bikes

-

成車&車架|Complete Bikes & Frames

-

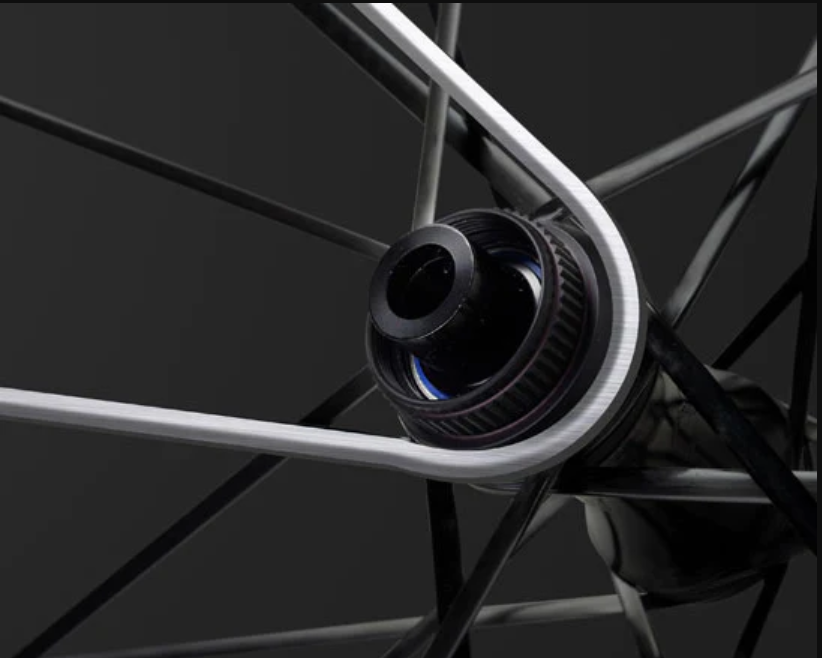

改裝配件|Upgrades & Components

-

Contact us